MAINTENANCE

My Journey With Car: Maintinance / Building / Modding

My Car Knowledge Developement

This page in my website is a place where I can "Blog" my learning about cars. I will post what I learn so that you guys can learn or see what I a learning! I want to expolre car: engines / extiriors / mods / turbos / wheels / and more!

How An Engine Works

Combustion, also known as burning, is the basic chemical process of releasing energy from a fuel and air mixture. In an internal combustion engine (ICE), the ignition and combustion of the fuel occurs within the engine itself. The engine then partially converts the energy from the combustion to work. The engine consists of a fixed cylinder and a moving piston. The expanding combustion gases push the piston, which in turn rotates the crankshaft. Ultimately, through a system of gears in the powertrain, this motion drives the vehicle’s wheels.

There are two kinds of internal combustion engines currently in production: the spark ignition gasoline engine and the compression ignition diesel engine. Most of these are four-stroke cycle engines, meaning four piston strokes are needed to complete a cycle. The cycle includes four distinct processes: intake, compression, combustion and power stroke, and exhaust.

Spark ignition gasoline and compression ignition diesel engines differ in how they supply and ignite the fuel. In a spark ignition engine, the fuel is mixed with air and then inducted into the cylinder during the intake process. After the piston compresses the fuel-air mixture, the spark ignites it, causing combustion. The expansion of the combustion gases pushes the piston during the power stroke. In a diesel engine, only air is inducted into the engine and then compressed. Diesel engines then spray the fuel into the hot compressed air at a suitable, measured rate, causing it to ignite.

IMPROVING COMBUSTION ENGINES

Over the last 30 years, research and development has helped manufacturers reduce ICE emissions of criteria pollutants, such as nitrogen oxides (NOx) and particulate matter (PM) by more than 99% to comply with EPA emissions standards. Research has also led to improvements in ICE performance (horsepower and 0-60 mph acceleration time) and efficiency, helping manufacturers maintain or increase fuel economy.

Learn more about our advanced combustion engine research and development efforts focused on making internal combustion engines more energy efficient with minimal emissions.

Top

Manual Automatic

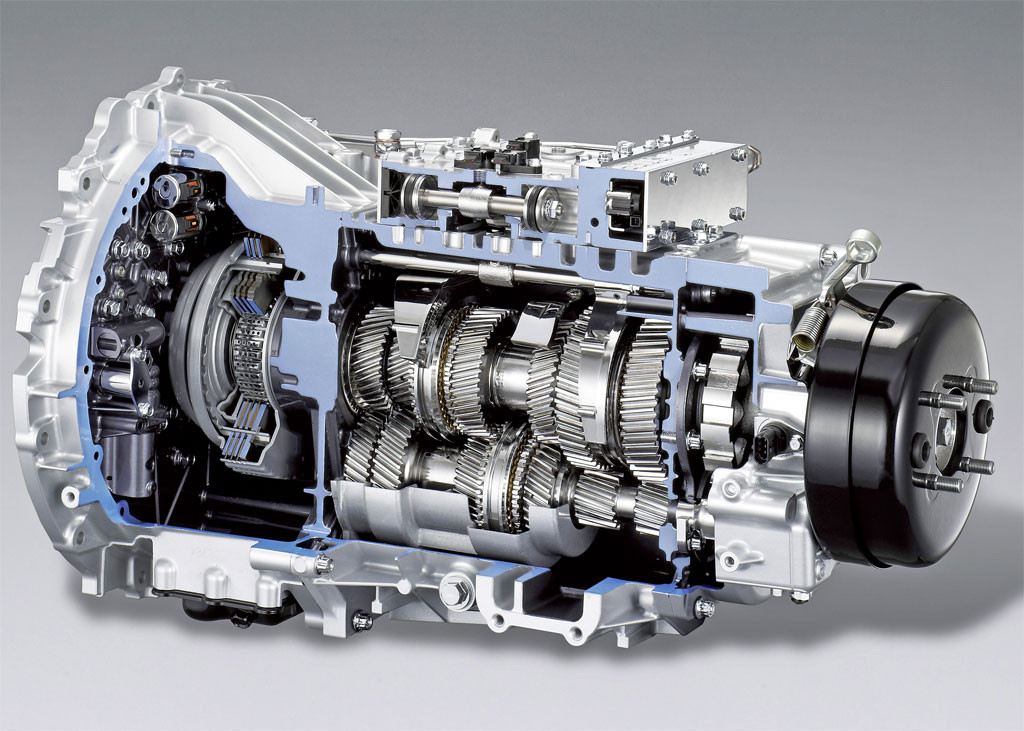

How A Transmition Works

If you've wondered about how a transmission works, the process varies depending on the type of transmission. Whatever type of transmission it is, the answer to what does a transmission do is to enable the gear ratio between the drive wheels and engine to adjust as the car slows down and speeds up.

When a vehicle is stopped, the transmission disconnects the engine from the drive wheels so that the engine can keep idling when the wheels aren’t in motion. Transmissions also enable quick acceleration from a stop and enable the engine to run more slowly to cut down on wear while the vehicle is driving at consistent speeds.

Manual Transmissions

Manual transmissions have a clutch pedal and a shifter the driver uses to manually change gears. These types of transmissions consist of a set of gears along a pair of shafts, called the input and output shafts.

How does a manual transmission work? With a manual transmission, the driver has to select the proper gear and engage or disengage the clutch. The transmission uses a flywheel, pressure plate and clutch to engage and disengage the engine from the transmission.

The flywheel and pressure plate are connected to the engine. The clutch is sandwiched between them and is splined to the transmission input shaft. The term “push in the clutch” means to release the pressure plate, which disengages the clutch from the engine. Every time you make a shift, you have to push in the clutch first.

The following are various types of manual transmissions.

Dual-Clutch

This transmission uses two clutches, which can be wet or dry. One clutch operates the even gears (2, 4 and 6). The other clutch operates the odd gears (1, 3, 5 and reverse). Dual-clutch transmissions were common in older cars and are still found in modern race cars. With today’s dual-clutch automated manual transmissions, sometimes called a double-clutch transmission or a twin-clutch transmission, a computer controls the clutch engagement and shifting, bridging the gap between a manual and automatic transmission.

Unsynchronized

The first manual transmissions were unsynchronized, or "non-synchro." They were also called rock crushers because drivers would grind the gears together trying to get them to mesh. Trucks used this type of transmission well into the early 1960s because these transmissions were very strong.

Synchronized/Constant Mesh

Synchronized/constant mesh transmissions keep the cluster gear, drive gear and mainshaft gears constantly moving. These types of transmission use pads to slow down the gears. This eliminates the need for double-clutching action.

Automated

An automated transmission, sometimes referred to as an AMT, is a manual transmission with a computer controlling the shifting and clutch. The AMT is used in heavy-duty trucks.

Single-Clutch

Single-clutch is a manual transmission with the computer controlling the shifting and clutch. Shifting and clutch control can be electric, hydraulic or electrohydraulic. The popularity of single-clutch transmissions started to fade as dual-clutches were able to handle increased torque.

Preselector

A preselector was a manual transmission with a vacuum or hydraulic shift control that was mostly used in the 1930s through the early 1950s. Some preselectors used bands and planetary gears. Basically, whatever forward gear was selected, the next time the clutch was engaged, it shifted to that gear.

Automatic Transmissions

How does an automatic transmission work? The main automatic vs. manual transmission difference is that with an automatic transmission, the process that powers a manual transmission happens within the transmission itself. Automatic transmissions typically don’t use clutches. Instead, the automatic transmission relies on a torque converter to change gears.

The first automatic transmission, which was more like a semi-automatic transmission because it still had a clutch, has been around in some form since the early 1900s. The first true automatic transmission used in a production car was the Hydro-Matic, in a 1939 Oldsmobile for the 1940 model year. The inventor was Earl Avery Thompson.

Most large SUVs and trucks have traditional automatic transmissions. Here are some terms commonly associated with automatic transmissions.

Direct-shift gearbox:

A direct-shift gearbox, also called a DSG, has two clutches that disengage alternately in changing gears. DSGs provide smooth acceleration and fast shifting. Tiptronic: A tiptronic gearbox allows an automatic transmission to be shifted manually, via the shifter and/or the steering wheel controls. The drawback is the computer will override/not allow manual mode if the transmission is outside the set parameters. Hydraulic: Hydraulic is the pressure/fluid inside an automatic transmission. What about electric cars? Single-gear systems are used in electric vehicles. The power band of an electric motor enables engineers to use compact single-speed transmissions to transfer power to the drive wheels. This can be integrated with the motor or be a bolt-on.

CVT Transmissions

Continuously variable transmissions, called CVTs, are pulley-based transmissions that are primarily used in small vehicles with small engines. CVTs have been used for years in snow machines, ATVs and side-by-sides, to name a few. They’re also more recently popular in hybrid vehicles.

The basic set-up is a primary small drive and a secondary large driven clutch, with a belt or chain to connect the two. The belt or chain will sit low in the primary drive and sit high in the secondary drive at a stop.

As you accelerate, the primary drive will contract, causing the belt or chain to walk up, while at the same time the secondary will expand, causing the belt or chain to walk down.